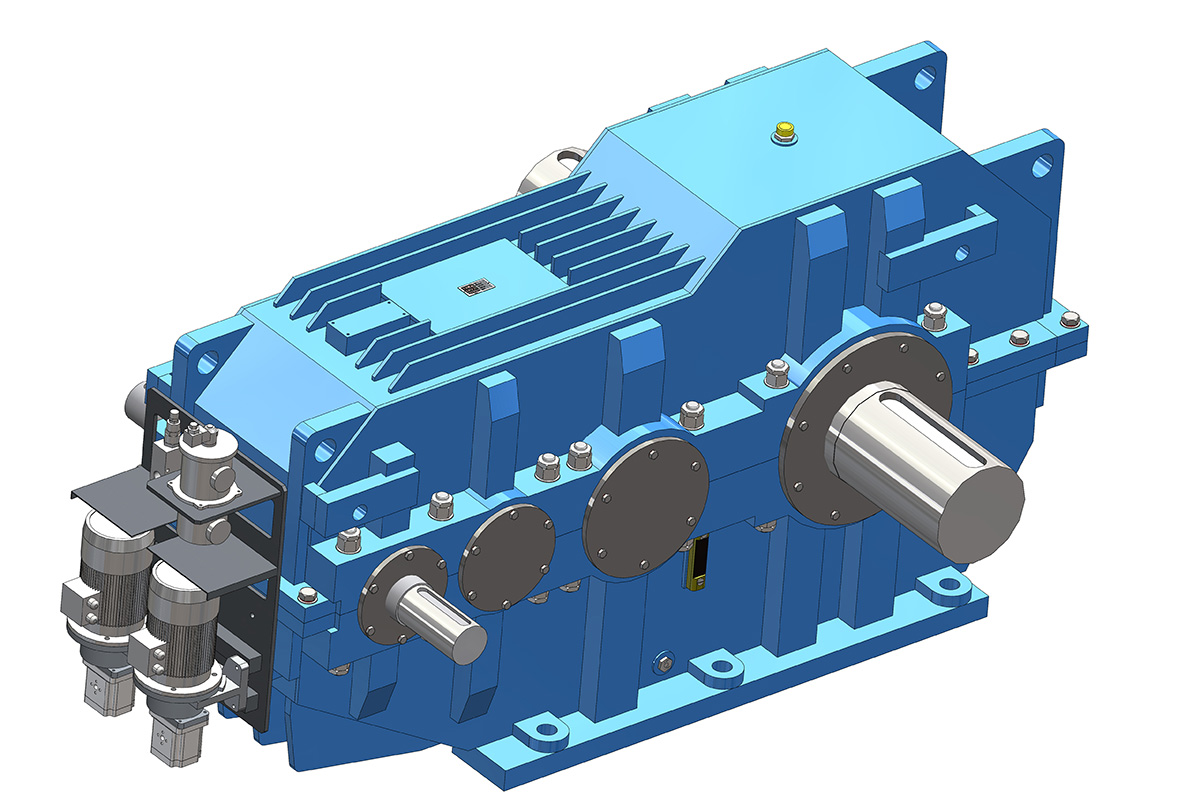

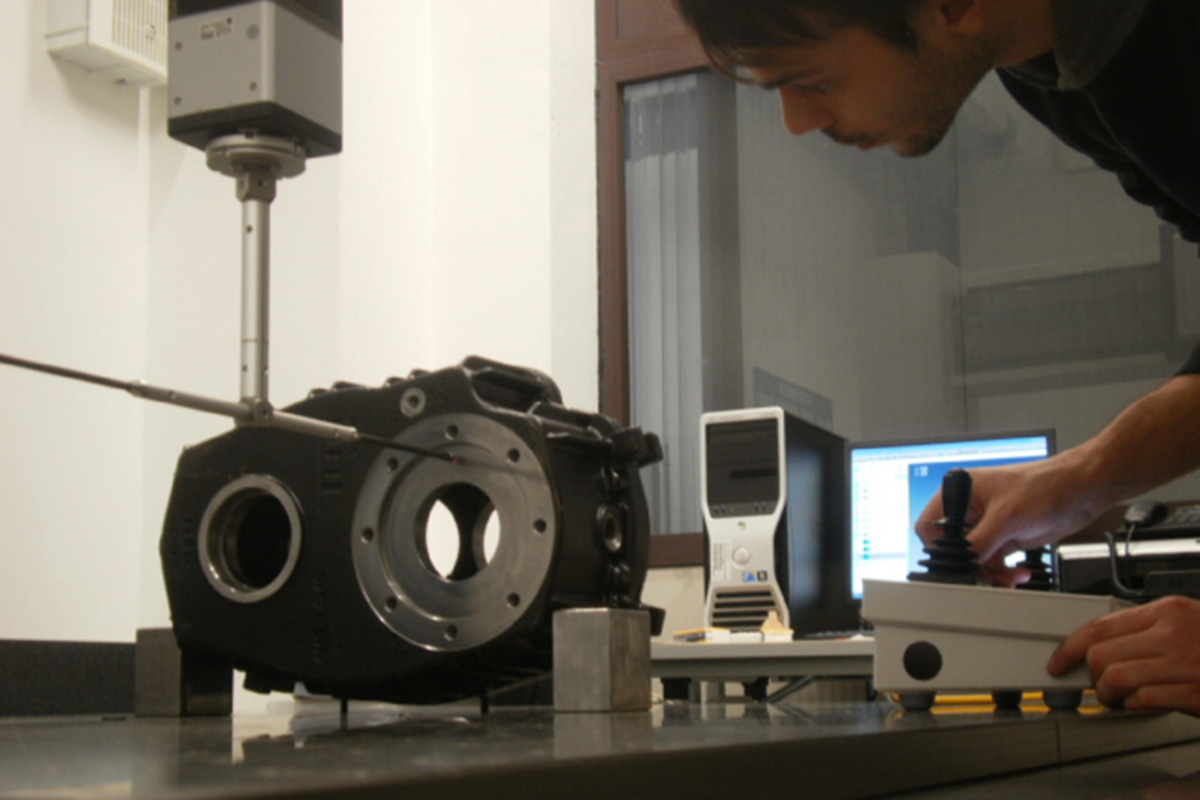

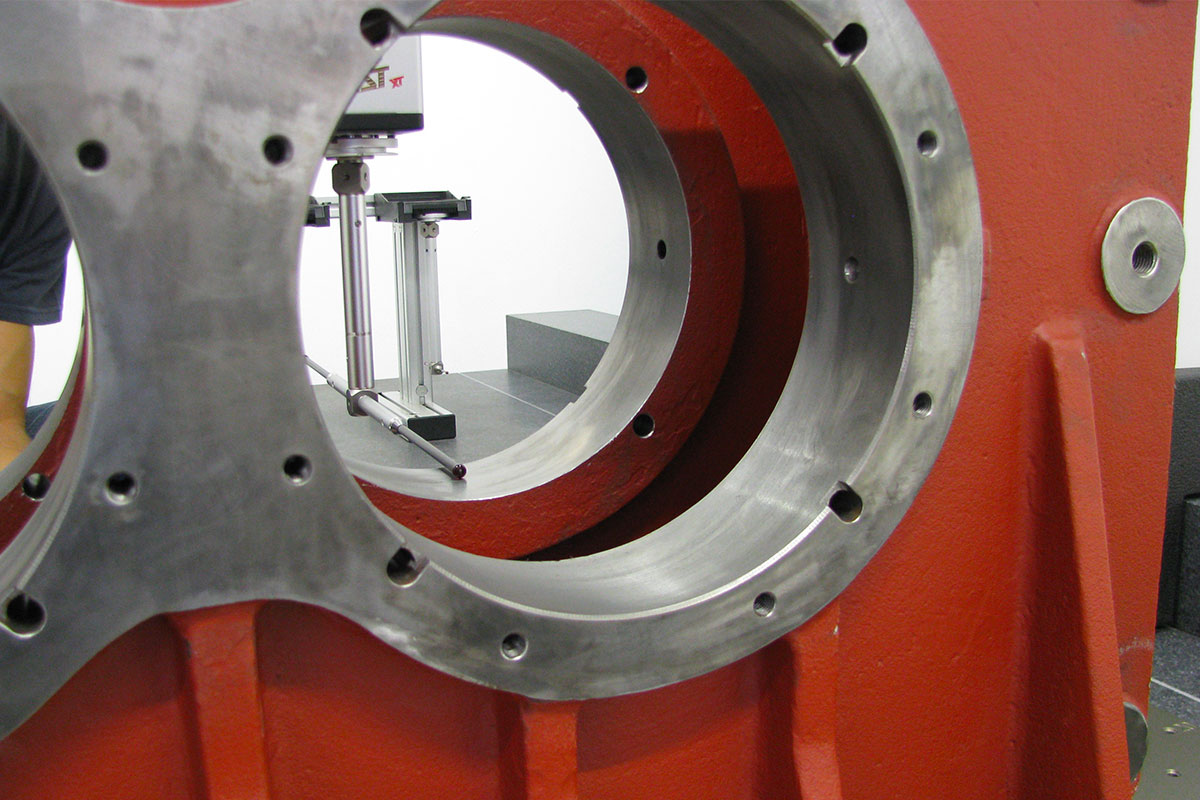

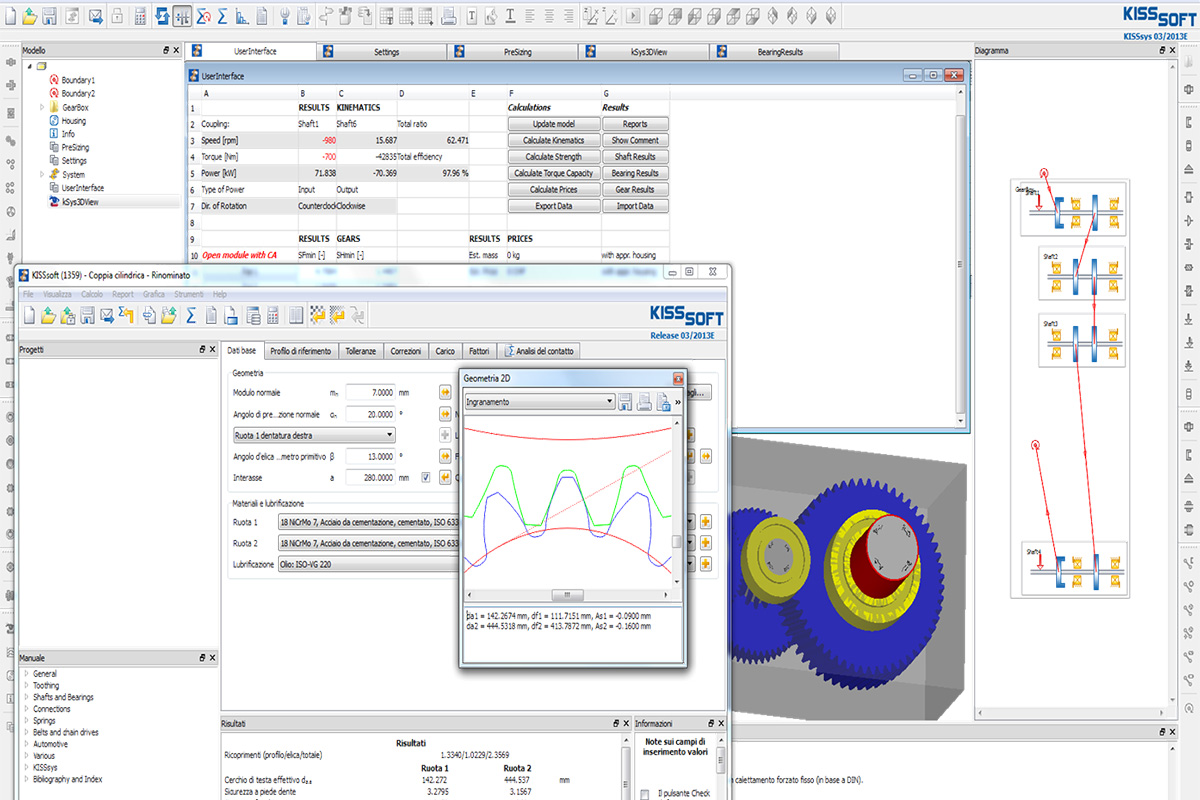

In the product engineering process, our experts make use of modern design software that fulfils ISO, AGMA and DIN requirements.

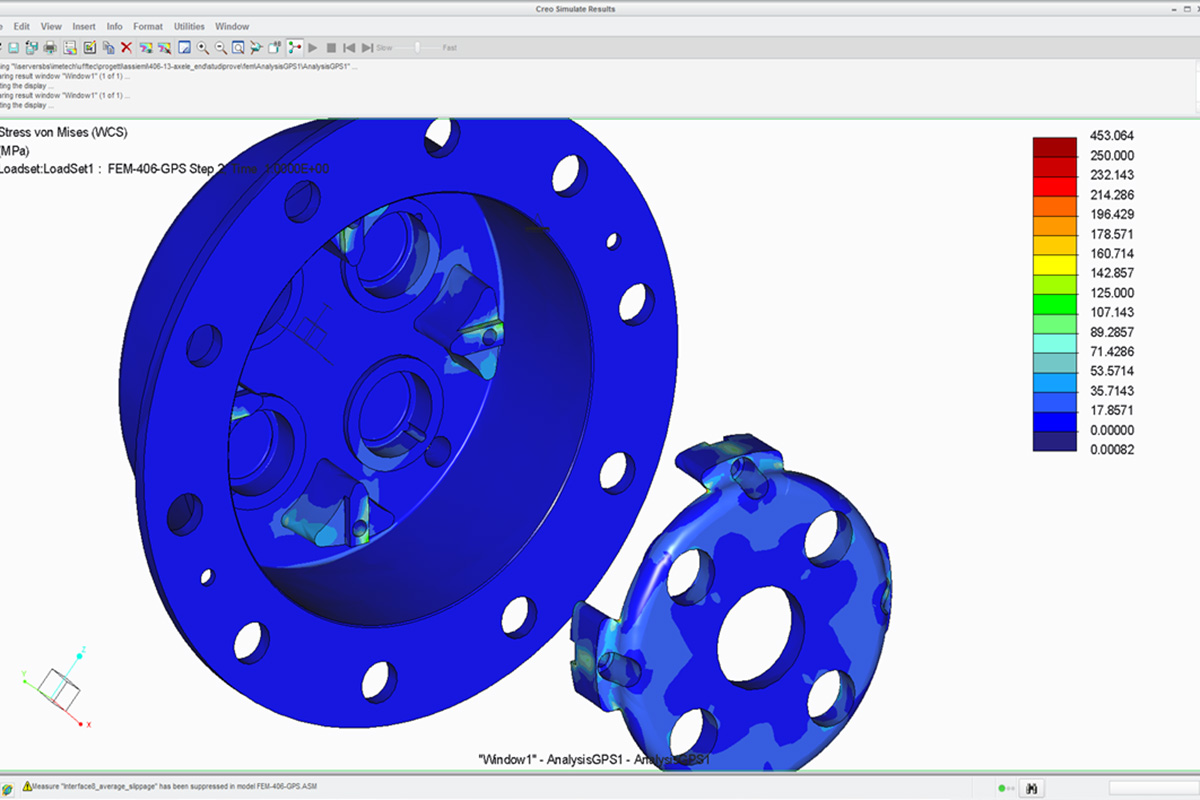

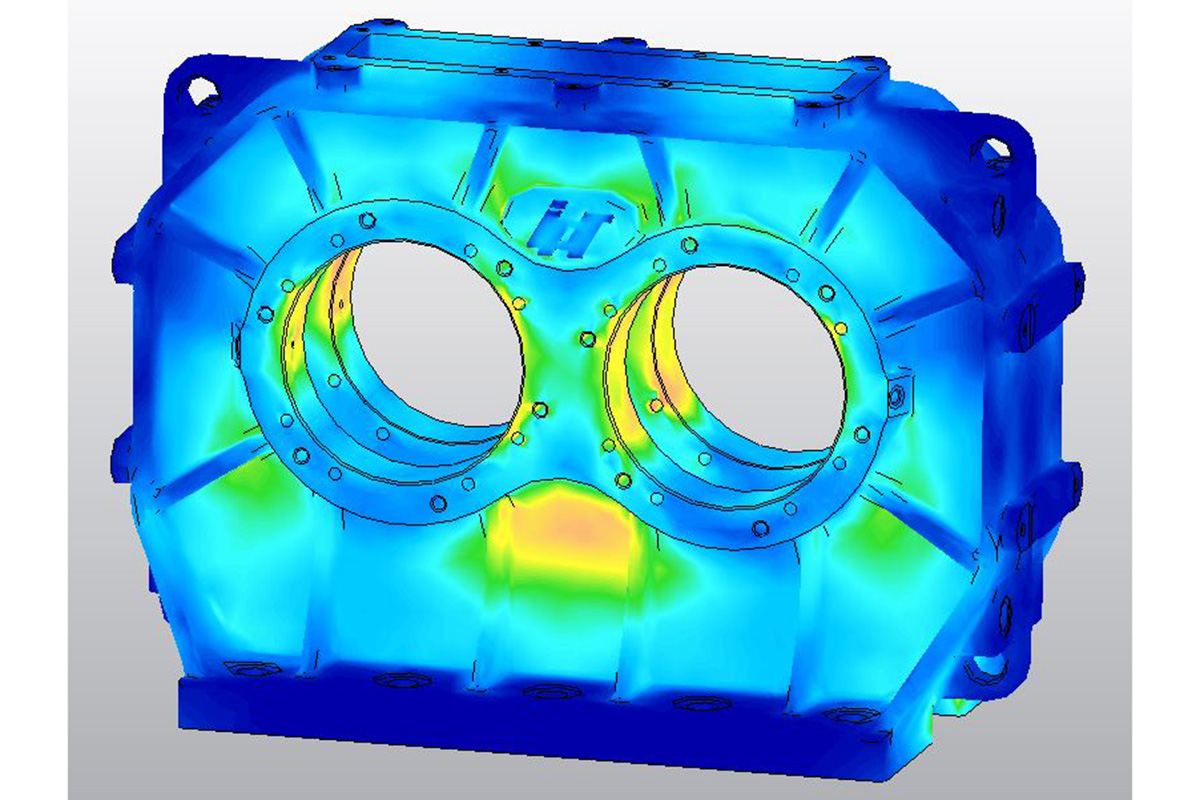

In order to control the extent of stresses and deformations, we use tools for finite element checks, so as to optimize the geometry of the components.

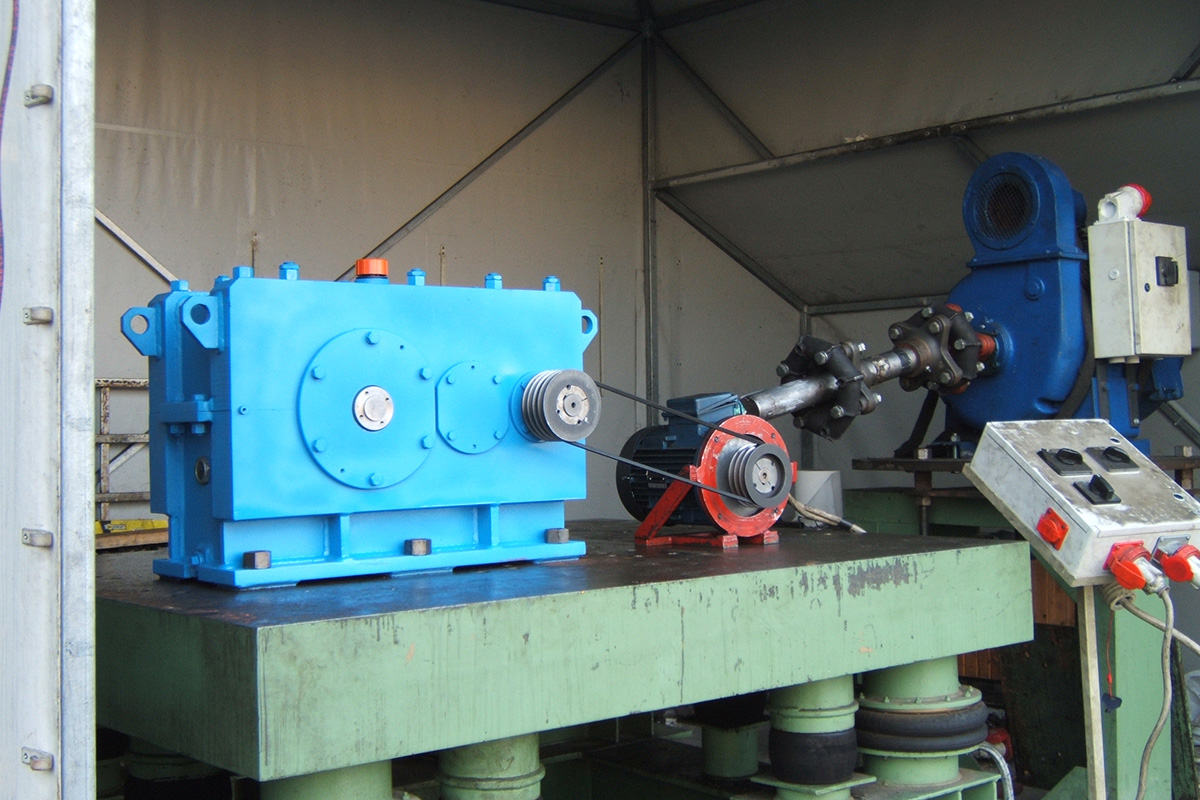

IMETECH has been collaborating for years with the Department of Mechanical and Industrial Engineering of the University of Brescia, participating in research and development projects.

Previous

Next